Rapid rollout for verification changes

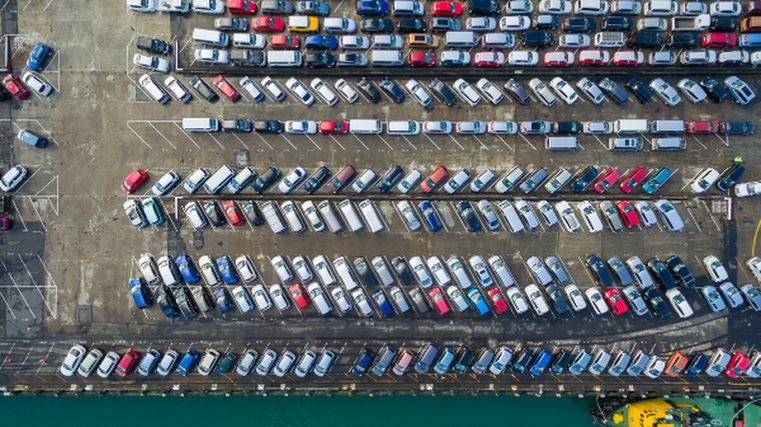

Biosecurity New Zealand plans to have a new system for handling used-imported vehicles fully operational by July 1.

Changes to the verification process will be rolled out over a two-month period in an effort to improve the system more than a year after Ministry for Primary Industries (MPI) officers were recalled from Japan because of Covid-19.

It is hoped the measures – revealed to representatives from across the used-car supply chain on April 23 – will help cut the time it takes to clear vehicles from ports.

The turnaround for roll-on, roll-off vessels was usually one or two days prior to the coronavirus pandemic but this year some ships carrying used vehicles have reportedly spent up to nine days in port.

Central to the shake-up is that Biosecurity NZ will no longer require cars to be held on a vessel for further inspection if contamination is discovered within a vehicle.

Instead, importers can have the consignment taken from the port to approved transitional facilities that are set to be based in Auckland, Wellington, Nelson and Christchurch.

Companies affected by the changes, which will begin on May 1, are expected to trial the new system for a few weeks before making a full transition by July 1.

The current approach by Biosecurity NZ to discharging vehicles will operate in tandem until the end of June to allow companies time to adjust to the new procedures.

Biosecurity NZ officers are also to continue operating from New Zealand, with initial plans for them to return to Japan once the threat of the coronavirus pandemic eased being shelved.

‘Reduced costs’

Government officials have been working with border inspection organisations (BIOs) based in Japan to create approved plans for onshore treatment.

Kevin Nalder, an independent biosecurity adviser for Autoterminal Japan, says he is happy with the changes being made by the MPI.

He describes the past year for the BIO as “unpredictable, expensive and stressful” and believes the initiatives discussed with the industry are a positive step forward.

“The changes are a step in the right direction so we can continue to move cars,” he explains.

“We would expect, based on our own analysis, there will now be a far greater number of verification passes.

“If the new measures are implemented as they have been proposed, there will be greater predictability along with fewer delays and logjams at the port. In turn, this should create more efficiency and reduced costs.”

Nalder says Autoterminal Japan will be working with transitional facility operators on a trial basis in May and hopes it can be fully operational by the end of the month.

“We simply have to adapt to the circumstances, deal with what we have and develop appropriate risk management to carry us into the future.”

Ports of Auckland (POAL) says it is working with the MPI and industry stakeholders to support a sustainable vehicle-inspection process and also welcomes the proposed improvements.

Spokeswoman Julie Wagener adds: “Ports of Auckland and the auto industry have worked hard to accommodate the changes to the biosecurity inspection process and manage the extended time vehicles are held at the port.

“The current process MPI put in place in 2020 due to Covid-19 was required, but was not designed as a long-term operating model.”