Marque to cut EV costs

Nissan has unveiled its way forward for electrified powertrain development, which it calls “X-in-1”.

Under the approach, core electric vehicle (EV) and e-Power components will be shared and modularised, resulting in a 30 per cent reduction in development and manufacturing costs by 2026 when compared with 2019.

Through the X-in-1 approach, Nissan aims to further increase the competitiveness of its EV and e-Power models.

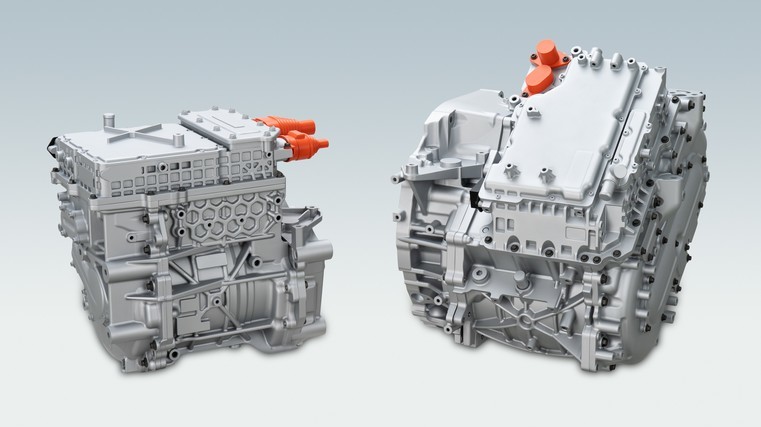

It has developed a 3-in-1 powertrain prototype, which modularises the motor, inverter and reducer, which is planned for use in EVs. A 5-in-1 prototype, which additionally modularises the generator and increaser, is planned for use in e-Power vehicles.

The X-in-1 approach, which covers 3-in-1, 5-in-1 and other possible variants, has been developed to enable core components to be produced on the same line.

In 2016, Nissan launched its unique e-Power electrified powertrain by utilising its EV technology, which provides the same driving pleasure as an electric car because it is 100 per cent motor drive.

It says the X-in-1 approach provides the following benefits:

• Size and weight reduction of the unit improves driving performance, and minimises noise and vibration.

• Adopt newly developed motor that reduces the use of heavy rare-earth elements to one per cent or less of magnet weight.

• The sharing of core components and control technology provides the enjoyable driving experience unique to Nissan EVs.

• Sharing and modularising core components improves production efficiencies and reduces powertrain costs by about 30 per cent compared to 2019.

• Nissan aims to achieve e-Power price parity with internal combustion engine vehicles by around 2026.

Under its long-term vision Nissan Ambition 2030, the company aims to bolster its line-up with 27 new electrified models, including 19 EVs, by fiscal year 2030.