Brake-by-wire on its way

Brebo and ZF Friedrichshafen have become the first suppliers to announce contracts for brake-by-wire systems that mainly do away with hydraulic components.

The way brakes operate hasn’t changed much since the 1920s when Augie and Fred Duesenberg equipped their Duesenberg Model A with four-wheel hydraulic brakes.

Now more precise computer-controlled electronic components are set to replace low-tech hydraulics.

Brake-by-wire can use artificial intelligence and algorithms to improve safety by shortening stopping distances, and keeping vehicles more stable under emergency braking.

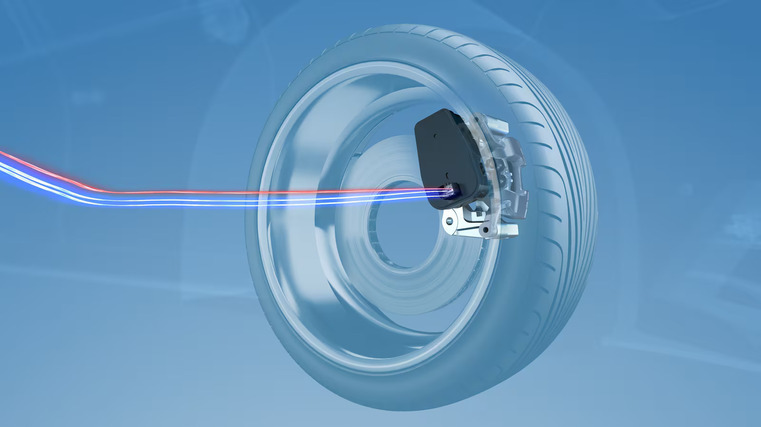

ZF, a German supplier known for automatic transmissions, also won’t name its first customer for its electro-mechanical braking (EMB) system, which is slated for release in 2028.

That said, Peter Holdmann, ZF’s chassis division head, told media at CES in Las Vegas in January that the company’s contract calls for it to equip five million units with EMB, pictured above, with 700,000 of those being heavy-duty pick-ups

Brebo’s Sensify system is expected to be launched next year. The company, which makes high-performance brakes for vehicles such as motorcycles, supercars and race vehicles, has yet to reveal its customer or in which market segment it will make its debut.

How brake-by-wire works

There are two types of brake-by-wire. The version that came out about a decade ago still uses hydraulics but has an electronic master cylinder, which measures driver intent when the brake pedal is pressed.

Brembo and ZF next-generations are “dry” in that they replace hydraulic calipers with electric ones that use motors to move the brake pads.

Traditional braking systems connect the pedal to the brake master cylinder and, usually, a vacuum-operated booster.

ZF’s EMB does away with most of that. The brake pedal is connected to an electric device that measures inputs such as the speed and force the driver uses when pressing the pedal

The tyres’ grip on the road creates another set of signals. A computer can apply different braking pressures to each wheel based on road conditions.

On cars with anti-lock brakes, the driver feels a buzz when the system engages. That will go away on vehicles with four-wheel brake-by-wire because the motors that press the pads against the rotors aren’t connected to the brake pedal.

The hybrid system

Brembo’s Sensify uses electronic components on all four wheels, which suggests its first application could be for an EV.

ZF’s EMB uses a combination of hydraulics for the front brakes, which provide most of the stopping power, and electronic components for the rear brakes, reports Automotive News.

It would be too expensive to equip a vehicle with an internal combustion engine to a 12-volt electrical system that has a redundant supply to safely operate the dry electric brakes on all four wheels in case of an electrical failure.

Bosch has a different type of brake-by-wire system that retains the hydraulically operated calipers, but uses fast-acting electronic actuation on the master cylinder, which routes brake fluid to the wheels.

There’s more to brake-by-wire than simply applying brakes faster. When brakes are applied, weight transfer occurs. The front of a vehicle gets heavier and rear tyres lose some grip.

Brake-by-wire systems, especially when used with cameras and AI, can more efficiently manage weight transfer and enhance safety under hard braking.