Blue oval on EV charge

Ford Motor Company is investing the equivalent of about NZ$2.18 billion in its Oakville Assembly Complex to transform it into a high-volume hub of electric vehicle (EV) manufacturing in Canada.

It’s a key part of the company’s plan to scale production of EVs and make them more accessible to millions of customers.

The campus, to be renamed Oakville Electric Vehicle Complex, will begin to retool and modernise in the second quarter of 2024 to prepare for production of next-generation EVs.

This marks the first time a full-line carmaker has announced plans to produce passenger EVs in Canada for the North American market.

The investment allows Ford to repurpose and transform existing buildings into a facility that leverages Ford of Canada’s skilled and experienced workforce.

Ford is taking a diverse strategic approach to transforming its industrial system to expand EV production – building new greenfield sites and also transforming existing manufacturing sites like in Oakville and Cologne, Germany.

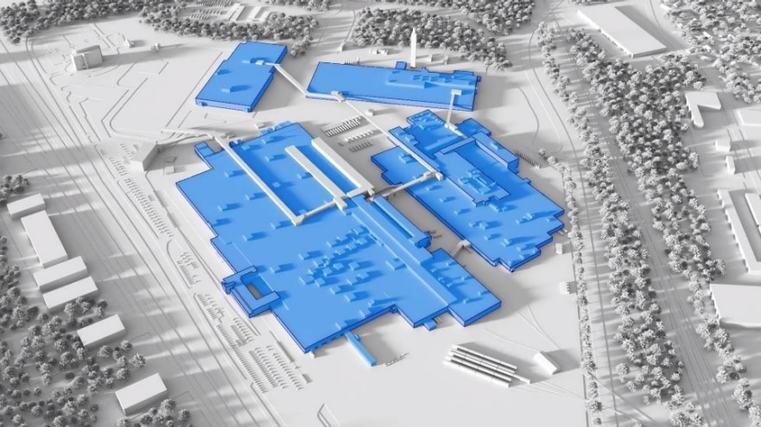

The current 487-acre Oakville site includes three body shops, one paint building and one assembly building. The transformed campus will feature an on-site battery plant that will utilise cells and arrays from BlueOval SK Battery Park in Kentucky. Oakville workers will take these components and assemble battery packs that will then be installed in vehicles assembled on-site.

In addition to the Oakville Electric Vehicle Complex upgrades, Ford has also announced it’s creating an all-new EV manufacturing ecosystem in West Tennessee – called BlueOval City – the home of a battery plant and the future home of the marque’s next-generation EV pick-up.

Through a wholly-owned subsidiary, Ford is building a lithium-ion battery plant in Marshall, Michigan. Production is slated to begin in 2026.

It is also modernising its vehicle assembly campus in Cologne, transforming it to become the Ford Cologne Electrification Center – the company’s first EV centre of excellence in Europe. This site will be electric Explorer will be built with production beginning later this year.

Ford, LG Energy Solution and Koç Holding have signed a non-binding memorandum of understanding to build on the largest commercial EV battery cell-production facilities in the European region. The project is on-track to break ground near Ankara, Turkey, later this year, with production to start in 2026.

Ford this year is expanding production of the F-150 Lightning at the Rouge Electric Vehicle Center in Dearborn and the Mustang Mach-E at its Cuautitlan facility in Mexico.